Newstalk Magazine is available now for free from the Apple app store.

Last week’s announcement by the EU Commission that a new innovation and research funding programme called Horizon 20/20 will be launched in 2014 creates an exciting opportunity for the design and manufacturing industries across Europe. The fact that the EU Commission has identified three dimensional printing technology as a key research driver for the development of innovative, marketable products, services and processes is also very welcome news for third level design academies, particularly here in Ireland.

For years, successive Irish governments have invested heavily in science and technology to achieve significant returns but have seriously overlooked the importance of design thinking and processes in terms of business growth, job creation and product development.

Of course, three dimensional printing has been around for more than thirty years but it has taken this long to reach a tipping point where the real potential and value of this technology can be fully realised. Large expensive machines, operated using very complicated software programmes, have progressively been replaced with smaller, less expensive and easier to use models.

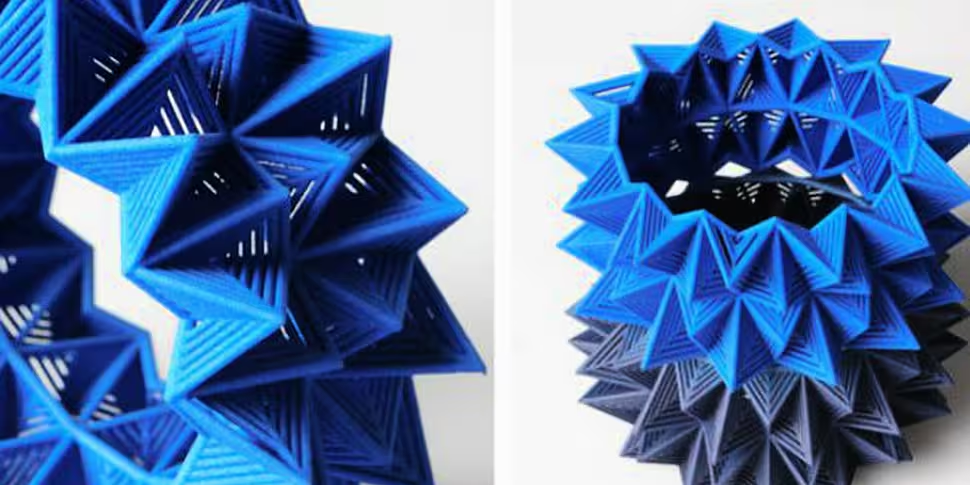

The advantages of three dimensional printing are that you can produce incredibly complex, accurate, structures that just could not be manufactured by other means. At present, the print material options are by no means infinite. Most users print in plastic but you can print in metal, ceramic, glass and plaster amongst others.

2011’s Award winning Gazelle clothes hanger, by Kevin Doherty and Ronan Murphy, NCAD

While most machines produce small objects, large printers have been made to build objects over three metres high. Some manufacturers are building machines specifically to recreate themselves. NASA uses this process on the space station. The most profound impact of three dimensional printing has been in surgical simulation and joint replacement technology in medicine. However, the trickle-down effect has been significant and opens up new vistas for strategic development in the manufacturing industries.

As the technology became more accessible, the use of three dimensional printing dramatically increased. Over the last seven years, through funded research partnerships, design staff and students at the National College of Art and Design (NCAD) have been providing a bespoke design service for business clients requiring this type of product development research.

The NCAD recently set up Origin8 as a technology transfer office to coordinate approximately fifty client-based funded research projects in the last calendar year, including business incubation and spin-outs. Much of this work is directed towards creating virtual and physical prototype designs aimed at computer aided manufacturing.

The prototypes are used not only to create an object that can be handled; they are used to test the market in small production runs or through focus group feedback. This is a form of lean manufacturing where you do not necessarily require an economy of scale. While this works very well for an iterative based innovation and research partnership with a client, this is the real advantage of using three dimensional printing in future manufacturing.

Three dimensional printing and related technologies such as laser and water-jet cutting are fast becoming everyday manufacturing tools to replace or augment traditional methods. At the NCAD our jewellery, fashion, graphic (packaging) and product designers are creating amazing, ‘one of a kind’ and batch production work in diverse materials and colours using this approach.

Theresa Burger, Earrings, Amashaza series, 2012

Most create products using a combination of components made by new technology and traditional studio methods. It should be pointed out that at this stage, very few three dimensional printers are capable of producing a finished object that does not require some form of post-production finishing, most frequently hand-finishing.

In Irish third level education, our biggest challenge is not our willingness to embrace new technology, it is in being able to afford the infrastructure and equipment to fully utilise and attract high calibre staff and students.

"Over the last twenty years Ireland became an epicentre for software development, and through the Horizon 20/20 innovation and research fund, it has the potential to do it again, only this time using design and new technology. If we are to generate marketable products, create employment and economic recovery, Ireland must focus on supporting and developing know-how.

We need examples of best practice in terms of research and innovation leading to creative enterprise. Australia provides an excellent working model where design is a now compulsory subject at second level education. Why? Because design thinking initially focuses on improving the way we interact with the world around us, finding better and more meaningful ways to live our lives.

Creative enterprise and economic growth occurs when design and manufacturing meet this objective.

Want to learn more about 3D printing? Listen to Sean Moncrieff’s interview with author Chris Anderson, formerly of Wired, about 3D printing.

Derek McGarry is Head of Design Innovation and Commercialisation at National College of Art and Design. See more of NCAD Origin8 work here

This article originally appeared in Newstalk Magazine for iPad in August, for more details go here.